Fighting Large Deformation in Tabaiyi Tunnel of the Jian-Ge-Yuan Highway in Yunnan-Guizhou Plateau NPR Anchor Cable Support Technology Achieves Greater Success

发布时间:2022年07月18日

浏览数:13107

The Jian-Ge-Yuan Highway is a key project in the "five-network" and comprehensive transportation in Yunnan Province. As a key project in Yunnan Province's "Thirteenth Five-Year Plan", it is in line with Yunnan Province's three strategies of "integrating into central Yunnan, linking north and south, and opening up development", which were fully implemented by Honghe Autonomous Prefecture. It is designed to become the transportation hub connecting Yunnan and ASEAN. The total length of the Highway is 124.53 km with a design speed of 80 km/hour. It has a bridge and tunnel ratio of 72%, and consists of the Jianshui-Yuanyang section and the Gejiu-Yuanyang section. A total of 29 tunnels (6 extra-long tunnels) will be constructed on the whole line, which is one of the most difficult highway projects currently under construction in Yunnan Province.

The Tabaiyi Tunnel, which is more than 2.6 km long, has been constructed for nearly 5 years. The construction progress has been severely delayed, affected by a series of geological disasters such as the large deformation of asymmetric soft rock, water gushing, mud intrusion, and collapse. It has become a "stuck neck" project for completing the whole line of Jian-Ge-Yuan Highway.

To solve the severe technical challenges faced by the Tabaiyi Tunnel, in 2021, China Power Construction Honghe Autonomous Prefecture Jian-Ge-Yuan Highway Co., Ltd. applied Academician Manchao HE's "NPR Anchor Cable Compensation Mechanical Support Technology" to the construction of the Tabaiyi Tunnel. After nearly a year of field testing, the major technical problem of large deformation of soft rock in tunnel construction under the complex geological conditions of the Yunnan-Guizhou Plateau was successfully solved. The Jian-Ge-Yuan Highway TJ7 project manager said, "We can now see the dawn of victory. We are confident to safely and efficiently advance the construction of the tunnel by using NPR anchor cable, and strive to achieve the early completion of the Tabaiyi Tunnel".

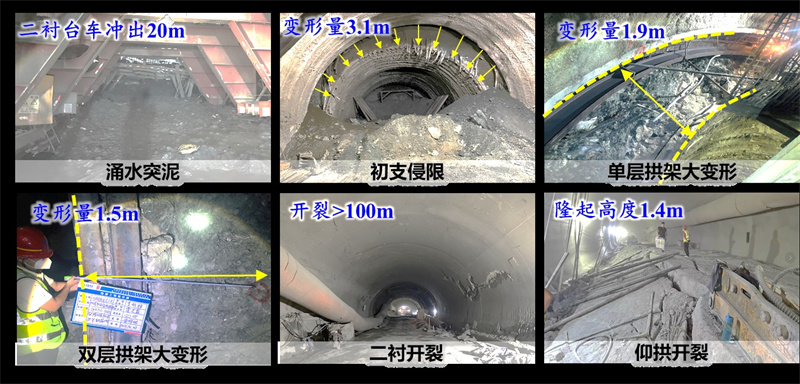

"Soft rock, large deformation, landslides, water gushing, mud intrusion, and collapse... the geological conditions of the Tabaiyi Tunnel were beyond conceivability, and the excavation was very difficult," recalled the engineers of the project. The overall surrounding rock of the tunnel is extremely fractured and is easily disturbed by large deformation of soft rock. The initial support settlement was greatly convergent, the initial support concrete was cracked, and seriously dropped, and the steel arch frame was seriously distorted and deformed. It is difficult to resist the deformation of the surrounding rock even if the protective arch was added in some sections, resulting in the cracking of the secondary lining and the uplift of the inverted arch.

To solve the rare problems encountered during the construction of the Hebaiyi Tunnel, ensure safe and efficient construction, and facilitate the early completion of the Hebaiyi Tunnel, a scientific research group led by academician Manchao HE entered the construction site On July 5, 2021 to carry out various preliminary tests, providing data support for the introduction of NPR anchor cable compensation support technology to this project. On October 14, 2021, the excavation compensation support technology with the high prestressed NPR anchor cable developed by Academician Manchao HE as the core material was officially put into use in the Tabaiyi Tunnel. This is the first time that the NPR anchor cable compensation support technology was applied in the fractured tunnels in the Yunnan-Guizhou Plateau.

For the remaining 70 m fractured zone in the Tabaiyi Tunnel, relying on the innovative structural recovery and strength compensation theory of Academician Manchao HE, the double-gradient grouting compensation technology for the crushed zone strength and the NPR anchor-net double-spacer and double-control technical industrial test were implemented in the Tabaiyi Tunnel. Through the core test of the surrounding rock, the pull-out test of NPR anchor cable, and the monitoring of settlement and convergence of surrounding rock, the effectiveness and feasibility of the above-mentioned innovative technology for fractured and broken tunnels are verified. This reserves advanced support technology for the extremely soft rock in the fault fracture zone that may be encountered in the remaining sections of the Tabaiyi Tunnel.

Criss-crossing Jian-Ge-Yuan Highway

The Tabaiyi Tunnel in the Jian-Ge-Yuan Highway Construction Project is a long-separated tunnel, located in the Jianshui-Yuanyang section, closer to the side of Yuanyang. It has a length of 2,616 m on the left side and 2,593 m on the right side, with a maximum buried depth of 297 m. It is a long deep-buried tunnel, sitting between the Longcha river arc compressive fault zone (F17) and the Hong river reverse deep fault (F14). During the excavation of the tunnel body section, it reveals that the surrounding rock is mostly a weathered slate with poor stability conditions, which makes the construction extremely difficult. The academician team and experts define the tunnel as a highway tunnel in the ultra-soft rock in fault zones with small distance and large section, which is rare in the world. It is one of the most difficult tunnels under construction in Yunnan Province.The Tabaiyi Tunnel, which is more than 2.6 km long, has been constructed for nearly 5 years. The construction progress has been severely delayed, affected by a series of geological disasters such as the large deformation of asymmetric soft rock, water gushing, mud intrusion, and collapse. It has become a "stuck neck" project for completing the whole line of Jian-Ge-Yuan Highway.

To solve the severe technical challenges faced by the Tabaiyi Tunnel, in 2021, China Power Construction Honghe Autonomous Prefecture Jian-Ge-Yuan Highway Co., Ltd. applied Academician Manchao HE's "NPR Anchor Cable Compensation Mechanical Support Technology" to the construction of the Tabaiyi Tunnel. After nearly a year of field testing, the major technical problem of large deformation of soft rock in tunnel construction under the complex geological conditions of the Yunnan-Guizhou Plateau was successfully solved. The Jian-Ge-Yuan Highway TJ7 project manager said, "We can now see the dawn of victory. We are confident to safely and efficiently advance the construction of the tunnel by using NPR anchor cable, and strive to achieve the early completion of the Tabaiyi Tunnel".

"Soft rock, large deformation, landslides, water gushing, mud intrusion, and collapse... the geological conditions of the Tabaiyi Tunnel were beyond conceivability, and the excavation was very difficult," recalled the engineers of the project. The overall surrounding rock of the tunnel is extremely fractured and is easily disturbed by large deformation of soft rock. The initial support settlement was greatly convergent, the initial support concrete was cracked, and seriously dropped, and the steel arch frame was seriously distorted and deformed. It is difficult to resist the deformation of the surrounding rock even if the protective arch was added in some sections, resulting in the cracking of the secondary lining and the uplift of the inverted arch.

To solve the rare problems encountered during the construction of the Hebaiyi Tunnel, ensure safe and efficient construction, and facilitate the early completion of the Hebaiyi Tunnel, a scientific research group led by academician Manchao HE entered the construction site On July 5, 2021 to carry out various preliminary tests, providing data support for the introduction of NPR anchor cable compensation support technology to this project. On October 14, 2021, the excavation compensation support technology with the high prestressed NPR anchor cable developed by Academician Manchao HE as the core material was officially put into use in the Tabaiyi Tunnel. This is the first time that the NPR anchor cable compensation support technology was applied in the fractured tunnels in the Yunnan-Guizhou Plateau.

NPR anchor cable construction

After the NPR anchor cable compensation support technology was applied in the Tabaiyi tunnel, the construction efficiency and quality were greatly improved. With the suspension effect of the high prestressed NPR anchor cable, the high prestressed compensation of the surrounding rock is carried out, which effectively restrains the large deformation of the soft rock in the Tabaiyi Tunnel. In the test section of NPR anchor cable compensation support with a length of 90m on the right line of the Tabaiyi Tunnel, the maximum deformation of the surrounding rock was sharply reduced from 3150 mm to within 300 mm, and the arch change rate achieved a breakthrough, namely from 70% to "0". By monitoring the settlement and convergence of the surrounding rock, the stress of the steel arch, the stress of the secondary lining, and the axial force of the NPR anchor cable, the reliability of the NPR anchor cable compensation support technology in preventing the large deformation of the soft rock in the fractured and broken tunnel in the Yunnan-Guizhou Plateau is effectively verified. For the remaining 70 m fractured zone in the Tabaiyi Tunnel, relying on the innovative structural recovery and strength compensation theory of Academician Manchao HE, the double-gradient grouting compensation technology for the crushed zone strength and the NPR anchor-net double-spacer and double-control technical industrial test were implemented in the Tabaiyi Tunnel. Through the core test of the surrounding rock, the pull-out test of NPR anchor cable, and the monitoring of settlement and convergence of surrounding rock, the effectiveness and feasibility of the above-mentioned innovative technology for fractured and broken tunnels are verified. This reserves advanced support technology for the extremely soft rock in the fault fracture zone that may be encountered in the remaining sections of the Tabaiyi Tunnel.

After the NPR anchor cable is applied

Adhering to the spirit of serving major national projects with science and technology, Academician Manchao HE led his R&D team to overcome the large deformation of soft rock tunnels with the supporting technology of NPR anchor cable, laying theoretical and practical foundations for the successful construction of many mega projects such as the Sichuan-Tibet Railway and the Central Yunnan Water Diversion.

中国岩石力学与工程学会微信订阅号

中国岩石力学与工程学会微信订阅号

科普岩石力学与工程

科普岩石力学与工程